Streamlined Machine Design With New Thomson Glide Screw™

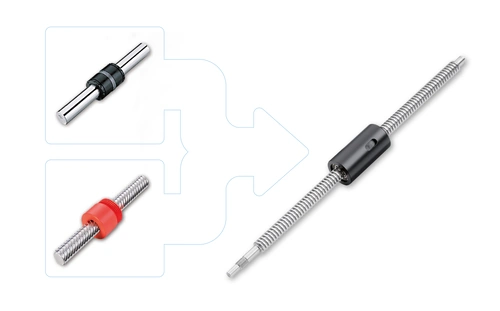

The Glide Screw™ is a breakthrough innovation from Thomson that combines the features of a linear bearing and a lead screw into one compact package. The patent-pending Glide Screw™ brings to you three tangible values: reduced footprint, improved equipment uptime, and lower cost of ownership.

■ Reduced footprint: Fewer components! – Integrated lead screw and linear bearing with no additional guidance needed.

■ Improved equipment uptime: Screw and linear bearing are already aligned.

■ Lower cost of ownership:

o Easy to install: Minimal prep time makes the install process fast.

o Minimal maintenance: Integrated Thomson Lube-for-Life lubrication block.

■ Custom configurations available: Special nuts, screw diameters and thread leads

available to accomodate your specific application.

Which applications are a great fit for the Glide Screw™?

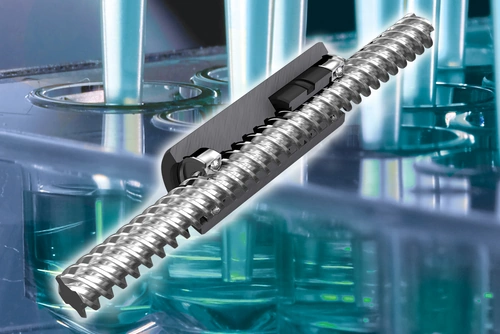

The Glide Screw was designed to solve the challenge where smaller, cleaner, smoother, and quieter mechanical motion products are required, e.g.:

- 3D printing and engraving

- Fluid pipetting / 3-axis lab automation

- Test tube handling

- CD duplication

- Pick & place

- Syringe pumps

- In vitro diagnostics

- Medical imaging

- Many others!

The Thomson Glide Screw is genuine innovation, unique in motion control, and available now.

LT

LT  RU

RU  EN

EN