LEAN and OEE monitoring

LEAN and OEE (Overall Equipment Effectiveness) are essential tools for evaluating and optimizing production processes. These methodologies enhance resource management, ensure product quality, and increase operational efficiency while reducing risks and downtime.

Key Benefits

- Enhanced Productivity: Real-time monitoring improves equipment utilization and minimizes downtime.

- Improved Quality Control: Ensures products meet established standards consistently.

- Cost Reduction: Identifies inefficiencies, reducing waste and operational costs.

- Data Transparency: Provides actionable insights for long-term process optimization.

Features

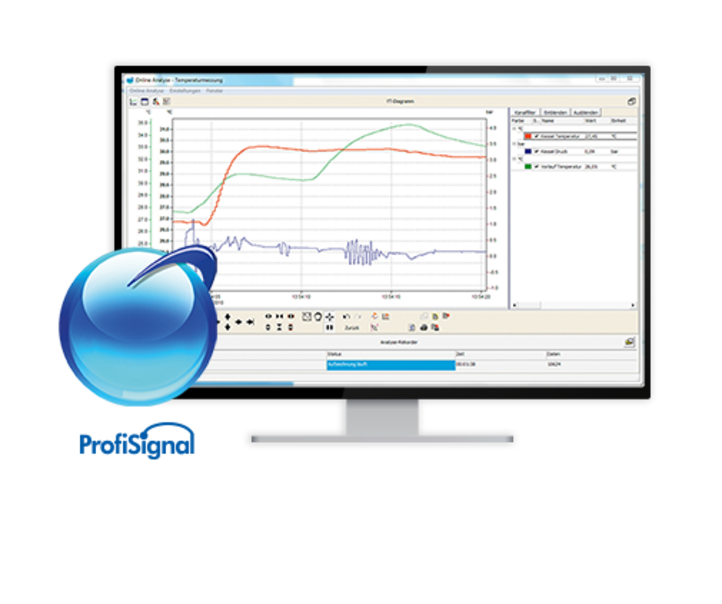

- Real-time tracking of production metrics.

- Data archiving for efficiency analysis and reporting.

- Identification of bottlenecks and elimination of inefficiencies.

- Integration with industrial protocols like ModBus and PROFIBUS.

Applications

- Manufacturing Lines: Boost operational efficiency and reduce delays.

- Energy Sector: Enhance equipment reliability and performance.

- Food Industry: Ensure compliance with safety and quality regulations.

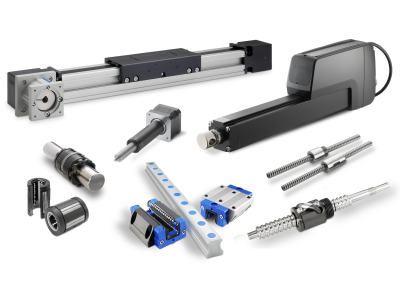

- Engineering and Automation: Optimize complex systems and improve reliability.

INOBALT's LEAN and OEE monitoring systems are the ideal solution for analyzing and optimizing production processes. Contact us today to find out how we can enhance your business performance.