Soft sensors

A soft sensor is a process model which uses readily available input data to predict output data.

PRODUCT OVERVIEW

Soft sensors serve the same function as physical sensors, except that values for the variable are not measured directly, but are obtained from a model of the physical sensor using other known variables as inputs. A soft sensor consequently enhances variable monitoring by increasing sampling frequency and replacing inaccurate measurements.

Soft sensors are typically used to replace sensors with high maintenance requirements, short life-spans, inaccurate sensors, and for variables where evaluation involves manual sampling and laboratory analyses. Since the physically measured value is often only returned from the lab a few days later, the immediately available predicted value from the soft sensor model can be used for control purposes.

IMPLEMENTING A SOFT SENSOR SOLUTION

Implementing a soft sensor solution requires a structured approach based on a sound understanding of the process as a whole, and specifically, variable measurements.

The procedure includes:

-

Data and information collection

-

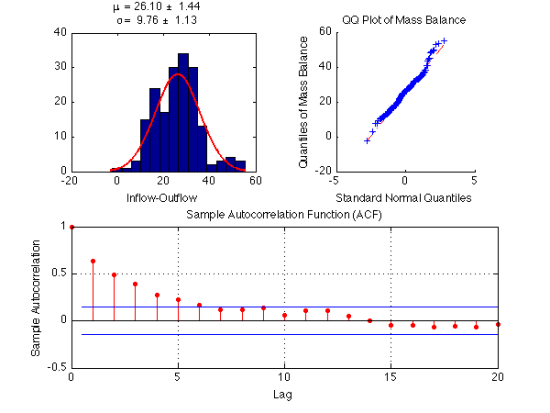

Data analysis and modelling

-

Soft sensor model design

-

New process knowledge and current expert knowledge amalgamation

-

Implementation and commissioning

-

Performance monitoring

Deploying the process model online as a soft sensor allows for continuous feedback for system monitoring and control. This is then used in conjunction with other Smart Process Monitoring applications for further process analysis and improvement.

BENEFITS

Use soft sensors to:

-

Save time and money

-

Enable better sampling

-

Develop a model to predict values that are not easily or quickly measured

-

Replace expensive sensors with high maintenance requirements and short life-spans

-

Replace inaccurate sensors providing noisy, drifting readings

-

For proactive, consistent and increased availability of measurements

-

Infer variable values on a continuous and real-time basis

-

Read data to a database for offline and online processing

-

Use modeled outputs to develop and implement online process monitoring and control strategies