Sensors, data loggers, automation

Sensors

Colour sensors

Inobalt colour sensors are ideal for industrial colour measurement and colour identification in virtually all production processes. The perceptive technology, which is equivalent to the precision of the human eye, also allows their use in quality control inspections. The sensors can identify and analyse not only colour changes, but also different surface structures.

Soft sensors

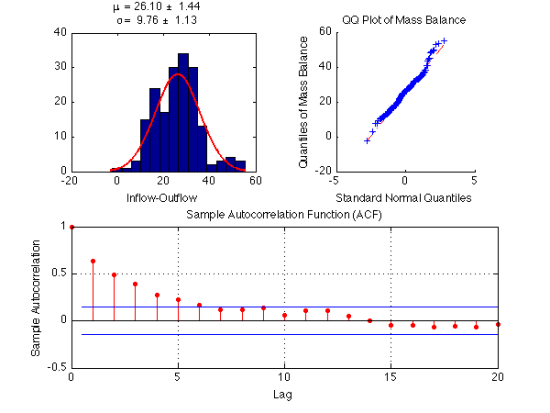

A soft sensor is a process model which uses readily available input data to predict output data.

PRODUCT OVERVIEW

Soft sensors serve the same function as physical sensors, except that values for the variable are not measured directly, but are obtained from a model of the physical sensor using other known variables as inputs. A soft sensor consequently enhances variable monitoring by increasing sampling frequency and replacing inaccurate measurements.

Soft sensors are typically used to replace sensors with high maintenance requirements, short life-spans, inaccurate sensors, and for variables where evaluation involves manual sampling and laboratory analyses. Since the physically measured value is often only returned from the lab a few days later, the immediately available predicted value from the soft sensor model can be used for control purposes.

IMPLEMENTING A SOFT SENSOR SOLUTION

Implementing a soft sensor solution requires a structured approach based on a sound understanding of the process as a whole, and specifically, variable measurements.

The procedure includes:

-

Data and information collection

-

Data analysis and modelling

-

Soft sensor model design

-

New process knowledge and current expert knowledge amalgamation

-

Implementation and commissioning

-

Performance monitoring

Deploying the process model online as a soft sensor allows for continuous feedback for system monitoring and control. This is then used in conjunction with other Smart Process Monitoring applications for further process analysis and improvement.

BENEFITS

Use soft sensors to:

-

Save time and money

-

Enable better sampling

-

Develop a model to predict values that are not easily or quickly measured

-

Replace expensive sensors with high maintenance requirements and short life-spans

-

Replace inaccurate sensors providing noisy, drifting readings

-

For proactive, consistent and increased availability of measurements

-

Infer variable values on a continuous and real-time basis

-

Read data to a database for offline and online processing

-

Use modeled outputs to develop and implement online process monitoring and control strategies

Vibration Sensors

|

|

|

|

4-20mA/Transmitter |

AC/Velocity sensors |

|

|

|

|

|

|

AC 100mV/g Accelerometers |

Triaxial Industrial Accelerometers |

|

|

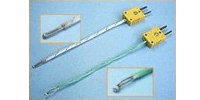

Thermocouples

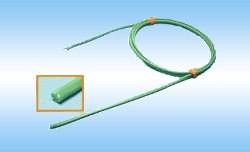

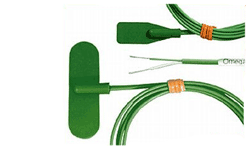

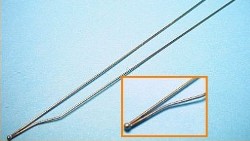

Thermocouple wires from original thermal material with different wire diameter. The wires are wound both individually and with a common fibreglass coat. Available for thermocouple types K, J, T, L and N. Standard equipped with a miniature connector and a free end with welded measurement nodes. For use in dry conditions for example Ovens, laboratory applications, etc. is ideal. Available in any length.

Thermocouple with fiberglass insulation and miniature connector |

|

|

|

Thermocouple with PTFE insulation and miniature connector |

|

|

|

Thermocouple probe tip with tightly sealed PFA (sterilized) |

|

|

|

Self-adhesive thermocouples, silicon jacketed for flat and curved surfaces |

|

|

|

Thermocouple with ceramic insulation and bare ends of connection (1 Form C) |

|

|

|

Thermocouple connection without insulation and bare ends (Form C) |

|

|

|

Thermocouple with ceramic insulation and bare ends of connection (type A, B and D) |

|

|

|

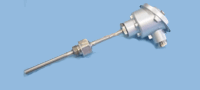

Temperature sensors

|

|

|

|

Contactless temperature sensors |

|

|

|

|

|

|

|

RTD sensors: PT100/PT500/PT1000 |

|

|

|

Compressed air, gases sensors

|

VA 420 Consumption counter for compressed air and gases

|

|

|

VA 400 Consumption sensor for compressed air and gases

|

|

Flow meters

|

|

|

|

|

Water/liquids flow meter |

Compressed air flow meter >> | |

|

|

|

|

|

|

|

|

Biogas flow meter |

Gas flow meter |

Condensate flow meter |

|

|

|

Steam flow meter

|

|

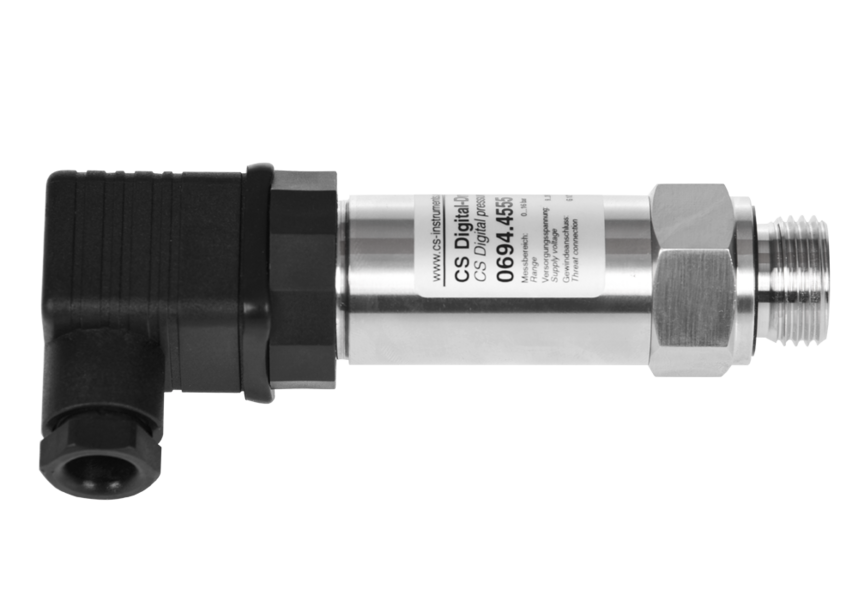

Pressure sensors

Pressure monitoring in compressed air and gas systems helps to significantly reduce energy consumption. Only a few types of machines actually require compressed air with more than 6 bar overpressure. A reduction in the nominal pressure reduces both the power consumption and the leakage losses and increases the service life of the compressor. Electricity savings in the range of 6 - 8% can be achieved by a reduction of the nominal pressure by only 1 bar.

The smaller the pressure drop across the filter, the less high the nominal pressure must be set. If the pressure drop across the filters is greater than 0.3 bar, the filters should be replaced. Our proven differential pressure sensors and pressure gauges are ideal to monitor those figures continuously.

Digital pressure sensor DPS 16

Measuring range: 0...16 bar

Signal:RS485

Process connection: G1/2"

Standard pressure sensor CS 10 and CS 16 for pressure ratio 0...10 and 0...16 bar measures with accuracy of full scale 1%. For more exactly measurement in the same pressure ratio we offer the CS 10/ CS 16 sensors with accuracy of full scale 0,5%.

Ouptup signal: 4...20 mA, 2-Wire

Power supply: 8...30 VDC

Standard pressure sensor CS 40

Standard pressure sensor CS 40 for pressure ratio 0...40 bar measures with accuracy of full scale 1%. For more exactly measurement in the same pressure ratio we offer the CS 40 sensor with accuracy of full scale 0,5%.

Output signal: 4...20 mA, 2-Wire

Power supply: 8...30 VDC

Standard pressure sensor CS 1.6 for pressure ratio 0...1.6 bar measures with accuracy of full scale 0,5 %.

Output signal: 4...20 mA, 2-Wire

Power supply: 8...30 VDC

Standard pressure sensor CS 100

Standard pressure sensor CS 100 for pressure ratio 0...100 bar measures with accuracy of full scale 0,5%.

Output signal: 4...20 mA, 2-Wire

Power supply: 8...30 VDC

Standard pressure senor CS 250

Standard pressure sensor CS 250 for pressure ratio 0...250 bar measures with accuracy of full scale 0,5%.

Output signal: 4...20 mA, 2-Wire

Power supply: 8...30 VDC

Standard pressure sensor CS 400

Standard pressure sensor CS 400 for pressure ratio 0...400 bar measures with accuracy of full scale 0,5%.

Output signal: 4...20 mA, 2-Wire

Power supply: 8...30 VDC

Precision pressure sensor CS -1...+15

Precision pressure sensor CS -1...+15 for pressure ratio -1...+15 bar measures with accuracy of full scale 0.5%.

Output signal: 4...20 mA, 2-Wire

Power supply: 8...30 VDC

Draw wire sensors

Draw wire sensors are suitable for measuring linear and non-linear motions. The compact style allows flexible and easy installation. Due to the small size, precise measurement is possible even in difficult applications.

|

|

|

|

| Product | Series SX50/ SX80/ SX120 | SX135 | Miniatursensor LX |

| Range | from 0-50...1250mm, 0-2000...3000mm, 0-3125...6000mm | 0-8000mm, 0-10... 11, 12, 15, 20, 25, 30, 40m | 0-50...1250mm |

| Measured value | position | position | position |

| Accuracy max. | ±0.01% | ±0.01% | ±0.1% |

| Output analog | 0...10V, 4...20mA, Potentiometer | 0...10V, 4...20mA, Potentiometer | 1Rk Potentiometer |

| Output digital | TTL, HTL, SSI, Profibus, CANopen, Interbus | TTL, HTL, SSI, Profibus, CANopen, Interbus | TTL |

| Protection class | IP65 (IP67) | IP65 (IP67) | IP00 |

| Data sheet | PDF EN RU | PDF EN RU | PDF EN RU |

|

|

|

|

| Product | Hydraulic transducer SX300 | HX with speed output | Display |

| Range | 0-1...15m | 0-100...50000mm | Incremental HTL |

| Measured value | position | position/ speed | Analog 0...10V, 4...20mA and Potentiometer |

| Accuracy max. | ±0.05% | ±0.1% | |

| Output analog | - | 0...10V, 4...20mA, Potentiometer | Limit values, sensor supply, RS232; RS485 |

| Output digital | TTL, HTL, SSI, Profibus, CANopen, Interbus | TTL, HTL | - |

| Protection class | IP65 (IP67) | IP68 | 24VDC, 230V |

| Operating pressure | Until 300 bar | / | / |

| Data sheet | PDF EN RU | PDF EN RU | PDF EN |

Position Sensors

|

|

|

|

Linear Potentiometer |

|

|

|

|

|

|

|

Ultrasonic Sensors |

Angle Transmitter + Encoder |

|

|

|

|

|

|

Laser Sensor |

Eddy Current Probe |

|

|

|

|

|

|

Digital Magnetic Scale |

|

|

|

|

|

|

|

Digital Ruler |

Magnetostrictive Sensor |

|

|

Optical sensors

Inobalt has an extensive portfolio of optical sensors in various models, light sources and functional principles for process-reliable detection, measurement and testing of even the smallest parts under challenging ambient conditions. Versatile and highly sensitive, Inobalt photoelectric sensors deliver long-distance, non-contact detection of metallic and non-metallic targets, accommodating variable target color and surface finish. High-frequency switching circuitry senses small, fast-moving objects, even against non-contrasting backgrounds. Photoelectric sensors direct light beams – emitted by a laser diode or LED – toward a distant target. Different operating principles detect either light reflected from the target (energetic-diffuse and background-suppression sensors) or the interruption of the beam by the target (reflex and through-beam sensors). Through-beam sensors utilize a separate receiver, allowing longer sensing distances. Other variants contain a transmitter and a receiver in a single housing. Conveying the light beam into confined spaces using optical fibers eliminates any electrical hazard at the sensing point, ideal for flammable atmospheres.

Level sensors

|

|

|

| Ultrasonic sensors | Contact sensors | Radar sensors |

Electric Sensors

M850 Multi-function Meters

|

The new range of multifunction panel meters feature 96 x 96mm sizes complete with unique blue LED screen. The range is easy to use and can be used on any single or 3 phase system with any input voltage without re-programming. The range is a cost effective replacement for traditional panel meters and is suitable for low, medium, and high voltage control panels, gensets, building management systems, power management and more. |

|

STANDARD FUNCTIONS

|

|

PROGRAMMABLE FUNCTIONS

All models feature the following user-programmable functions:

- Current Transformer Ratio

- Voltage Transformer Ratio

- Baud Rate, Parity, Stops

- AC or DC AUX

- 1A or 5A CT

- Single or 3 phase system

- Input voltage range 28-570V

- RS485 address, 1-247

- Security code access for programming

CURRENT SENSOR

| Clamp-on ammeter 0...1000 A TRMS incl. 5 m connection cable with open ends |

|

Dew point meters and measurement tools for compressed air and gases

The choice of the correct measuring device is decisive for correct dew point measurement and humidity measurement in compressed air and gas. Dew point measurement and monitoring in compressed air systems is essential. Drying of granulate in plastics technology, the generation and usage of various technical gases (N2, O2, Ar, H2) and a lot more applications require professional dew point measurement equipment for perfect operation. Proven and reliable dew point meters from CS Instruments are helping customers worldwide to ensure the required product quality in compressed air and gas systems.

As experience manufacturer of dew point sensors CS Instruments offer a wide and field proven product portfolio for dew point sensors. Our delivery program includes especially designed stationary and mobile solutions for dew point monitoring of refrigeration, desiccant or membrane driers. Ideal accessories like measuring chambers, dry containers or diffusion tight hose ensure that CS dew point systems are the perfect solution for a trouble-free dew point measurement.

Standard interfaces are 4…20mA, Modbus RTU or M-Bus. Furthermore, all dew point sensors can be combined easily with our data loggers. Dew point sensors form CS Instruments enables a reliable and long-term stable monitoring of the pressure dew point in industrial applications from -80 to +20 °C dew point. We recommend the indirect installation with measuring chamber. This enables easy mounting and dismounting of the probe without interruption of the line, a quick response time and optimum sensor protection.

Sensors

Inobalt offers a comprehensive range of standard and special sensors for industrial automation. Choose between different functional principles, models, switching sensors and measuring sensors for efficient and trouble-free system operation.

Linear Variable Differential Transformers (LVDT)

Linear Variable Differential Transformers (LVDT) are ideal for applications in harsh industrial environments such as high temperature and pressure applications, dynamic applications and long term cycles.

|

|

|

|

| Product | SL | SM | SM-HYD |

| Range | 50 - 600 mm | 2 - 200 mm | 2 - 180 mm |

| Construction | rod end bearing, only push rod guided, push rod extricable | only push rod guided, push rod extricable | push rod guided |

| Linearity max. | ±0,3 %, optional ±0,2 % | ±0,3 %, optional ±0,2 % | ±0,3 %, optional ±0,2 % |

| Output analog | AC, 0...10 V, ±10 V, 0...5 V, ±5 V, 4...20 mA, 0...20 mA | AC, 0...10 V, ±10 V, 0...5 V, ±5 V, 4...20 mA, 0...20 mA | AC, 0...10 V, ±10 V, 0...5 V, ±5 V, 4...20 mA, 0...20 mA |

| Voltage rate | 24 V (9...36 VDC) | 24 V (9...36 VDC) | 24 V (9...36 VDC) |

| Power input | from 65 mA | from 65 mA | from 65 mA |

| Protection class max. | IP67 (optional IP68) | IP67 (optional IP68) | IP67 (optional IP68) |

| Operating temperature | -40 °C..+120 °C, +150 °C (only sensor) | -40 °C..+120 °C, +150 °C (only sensor) | -40 °C..+120 °C, +150 °C (only sensor) |

| Operating pressure | - | - | 400 bar |

|

|||

| Product | SM-F18 | ||

| Range | 2 - 200 mm | ||

| Construction | rod end bearing | ||

| Linearity max. | ±0,3 %, optional±0,2 % | ||

| Output analog | AC, 0...10 V, ±10 V, 0...5 V, ±5 V, 4...20 mA, 0...20 mA | ||

| Voltage rate | 24 V (12...36VDC), 15V (12...18VDC) | ||

| Power input | 24 V (9...36 VDC) | ||

| Protection class max. | IP67 (optional IP68) | ||

| Operating temperature | -40 °C..+120 °C, +150 °C (only sensor) | ||

| Operating pressure | 150 bar |